Canada is witnessing an exciting surge in electric vehicle (EV) growth. With more consumers and companies turning toward cleaner transportation, this means more factories, assembly lines, and storage facilities are needed to support production. Steel buildings are becoming key players in this transformation. Their strength, versatility, and quick assembly make them ideal for EV projects. In this article, we’ll look at how steel structures are shaping the EV industry and helping the country keep up with rising demand.

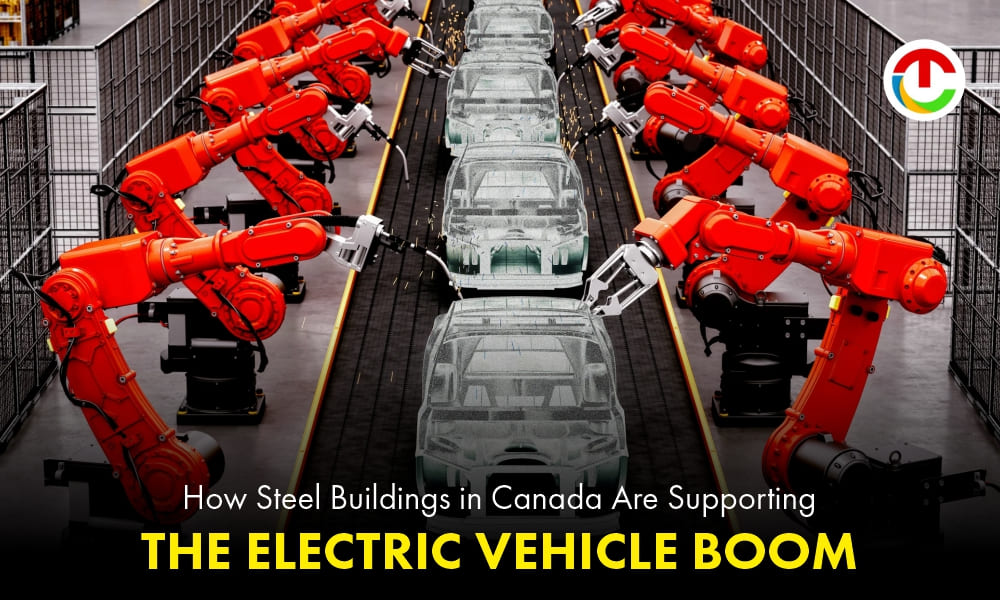

Accelerating EV Manufacturing

One of the biggest advantages of using canada steel buildings is how quickly they can be built. EV factories require huge, open areas that can fit production lines, equipment, and warehouses all under one roof. Steel construction makes that possible in a shorter time than traditional methods like concrete or brick. This speed gives Canadian automakers a vital edge: they can start production faster, reduce downtime, and respond more easily to market changes. The faster the facilities go up, the sooner vehicles can roll off the assembly line.

Flexible Facility Design

Steel buildings can be adapted almost endlessly. Whether a company needs tall ceilings for robotics equipment or wide bays for vehicle storage, the structure’s framework can be adjusted to match. Manufacturers appreciate this flexibility because it allows them to get the most out of their space. If production needs change, steel buildings can be expanded, rearranged, or reconfigured with less hassle. That’s a big plus when the EV industry itself is evolving rapidly.

Faster EV Plant Construction

In many cases, conventional construction can delay operations for months or even years. Steel, on the other hand, can be prefabricated and assembled quickly once it arrives on site. This cuts down the total build time significantly. A faster setup saves money and reduces risk for companies entering the EV space. In such a competitive field, especially in Canada, time is often as valuable as the final product itself.

Strengthening the EV Supply Chain

The growth of electric vehicles is as much about the car factories as it is also about everything that supports them: warehouses, distribution hubs, and battery component centers. Steel buildings make it easier to create these links quickly, offering strong and easily maintained spaces across the country. Whether it’s an urban logistics center or a regional assembly point, steel provides the durability and adaptability these operations need. This kind of infrastructure helps maintain a steady flow of parts and finished vehicles throughout Canada.

Supporting Remote Assembly Sites

Not every EV facility is built in a major city. Many projects are expanding to remote or developing regions where space is available and growth potential is high. Steel buildings work well in these areas because they can be transported in parts and assembled with fewer heavy machines. Even in harsh weather conditions or limited-access zones, construction can move ahead smoothly. This flexibility ensures that EV production isn’t limited to urban centers but reaches more parts of the country.

Durable and Sustainable Solutions

Steel has a long lifespan and is one of the most recyclable materials available. For the EV industry, which values sustainability, this makes steel an ideal choice. Manufacturing companies using buildings made from it align their facilities with environmental goals by reducing waste and maximizing material reuse. These durable, sustainable structures cut long-term costs and reflect the broader mission of Canada’s clean transport revolution.

The advantages of practicality, speed, and adaptability with environmental responsibility make canada steel buildings a quiet but powerful force in Canada’s electric vehicle expansion. From large manufacturing centers to supply chain warehouses, steel structures make it easier for the EV industry to grow and stay sustainable. As the country continues to strengthen its position in the global market, steel will remain an essential component of that progress: supporting innovation, efficiency, and cleaner technology across the country.